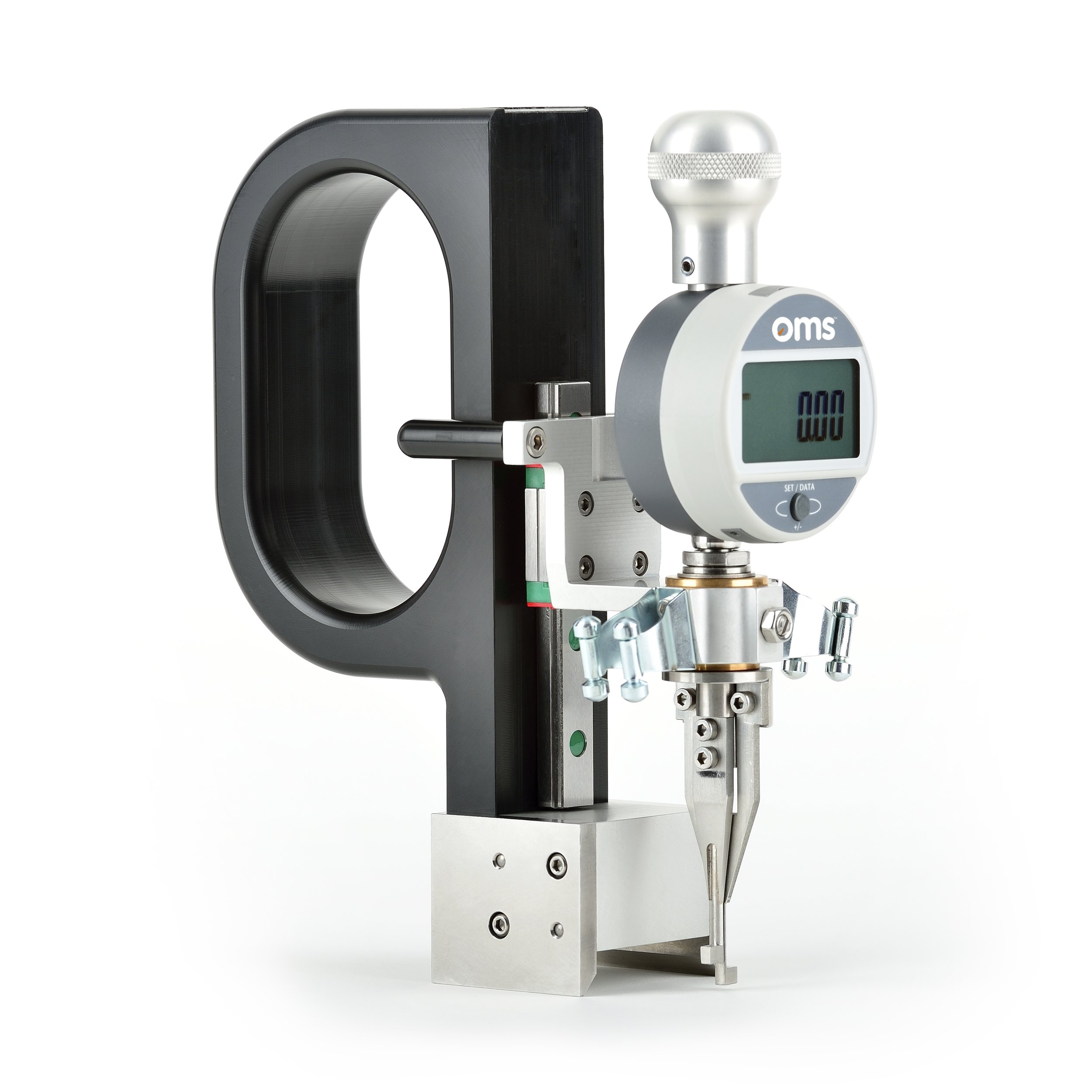

HiLo measurement

Our Open Gap and Closed Gap HiLo tools measure internal and external pipe geometry to a high degree of accuracy, leading to higher quality welds and stronger pipelines. Ideal for critical fatigue-sensitive pipeline sections such as steel catenary risers, these tools been used around the world by all major pipe-lay companies and welders. Our team are available at any time to discuss your requirements - contact them.

Key features:

Reduce HiLo

Measurements accurate to +0.05mm

Ensure design specifications are met

Easy to use with magnetic base and calibration/verification stand

Traceable measurements

Range of blades available to suit requirements

Further customisation is available on request

“Measuring HiLo just before welding confirms the best fit-up selections for critical fatigue-sensitive pipes and reduces the chance of expensive weld-related cut outs”

Better pipe fit-up

Created in response to customer request, OMS HiLo tools measure the pipe geometry of two pipes aligned for welding to a high degree of accuracy. OMS sales director, Paul Eagle, writes about what HiLo measurement is and why it is important.

Final check before welding

To achieve a good weld and avoid stress concentration pipes must be matched as accurately as possible. In critical fatigue sensitive pipes the HiLo measurement confirms fit-up predictions from the OMS SmartFit process and provides the last check before pipes are welded. Post-weld, pipes may be checked again with OMS weld inspection technology.

Simple pipe inspection

Our HiLo toosl use standard digital gauges, are simple to operate and will be familiar to pipe inspectors. All OMS tools are sent out calibrated and we provide a yearly calibration and repair service.