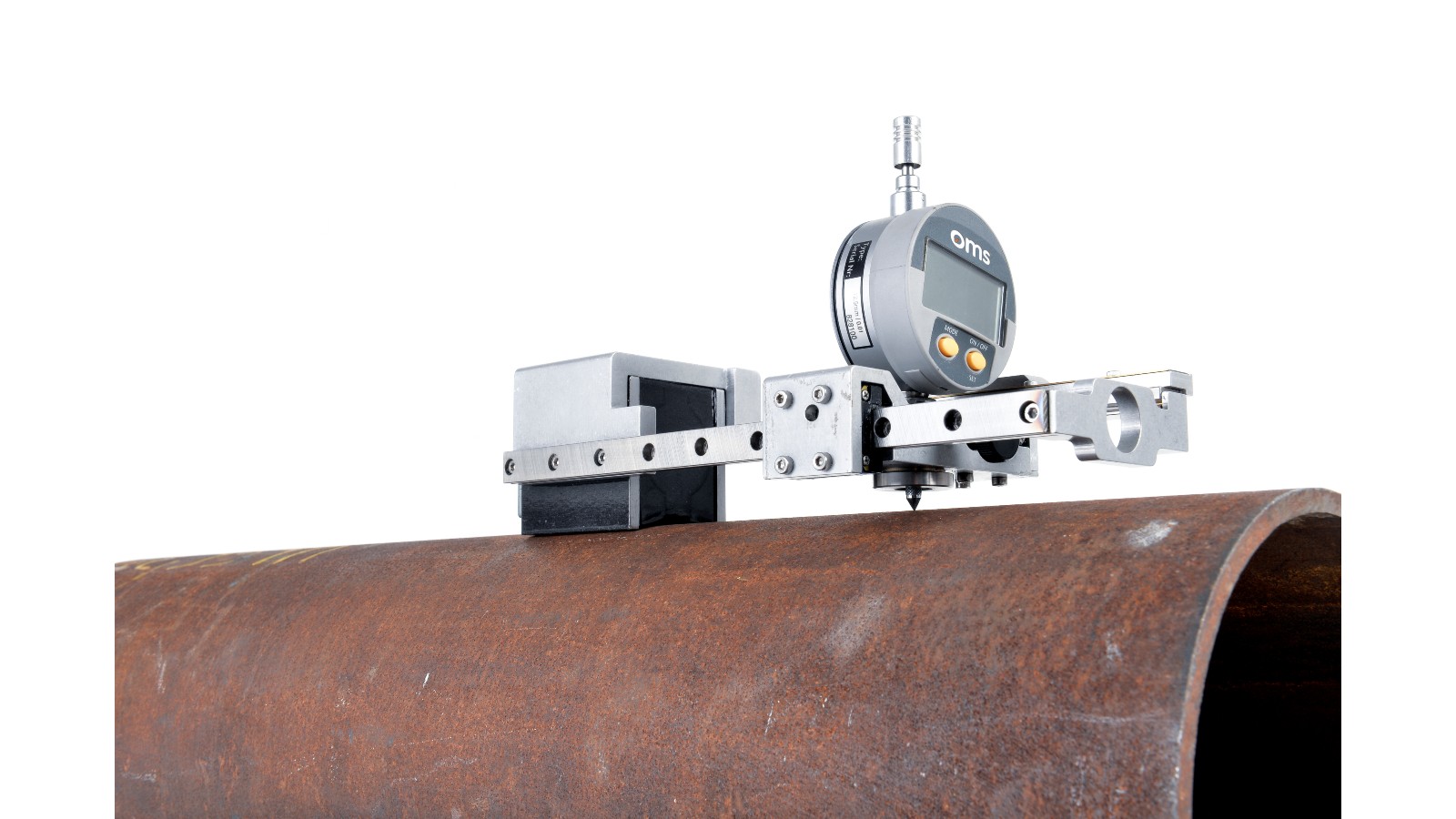

Pipe Girth Weld Measurement

The Pipe Girth Weld Measurement Tool is designed to allow the operator to determine the deviation of a pipe wall across a weld.

Key features

Measures weld contour and grinding

Lightweight with magnetic clamp

Measurement at any distance

Calibrated dial gauge with hardened measurement probe

Traceable and repeatable measurements

Determine weld flushing shape

We designed the Girth Weld Tool to help our customer to determine the shape of any weld flushing. Measuring the shape of the weld and the surrounding area makes it possible to calculate pipe wall thickness. If welds are over-ground pipe wall thickness can be reduced to a point where pipe fatigue life can be compromised. Weld flushing minimises fatigue in the weld region by smoothing out the shape of the weld and any undercuts where cracks could form.

Calibrated digital indicator

The OMS Girth Weld Tool comprises a magnetic clamp to attach the tool to the pipe, a pair of linear rails which are preset highly parallel to the clamp and a moving carriage which carries the calibrated digital indicator. The operator zeroes the dial gauge on one side of the pipe before checking along the weld until all minimum and maximum values have been logged. The carriages are parallel to the underside of the magnetic clamp and the dial gauge is mounted in a precision rotary bearing, making it easy for the operator to view and note readings.