Improving weld strength with grinding

Ensuring welds are strong and fit for purpose is of vital importance within energy production. In every pipeline each weld is a potential fault line on which the entire structure depends. Weld defects are a major cause of pipeline failure and have led to some of the most serious pipeline disasters in history.

The energy industry has an enormous range of welding requirements, from small diameter pipes to offshore oil rigs; to the jackets that support enormous wind turbines and many other applications. Pipelines and tubes play a vital role in transportation of hydrocarbons both fossil fuels, renewable energy assets where they support transmission cables. If weld defects are present within tubes or pipelines then operations can be affected, leading to expensive downtime and repairs, or even a potential disaster.

Most common weld defects

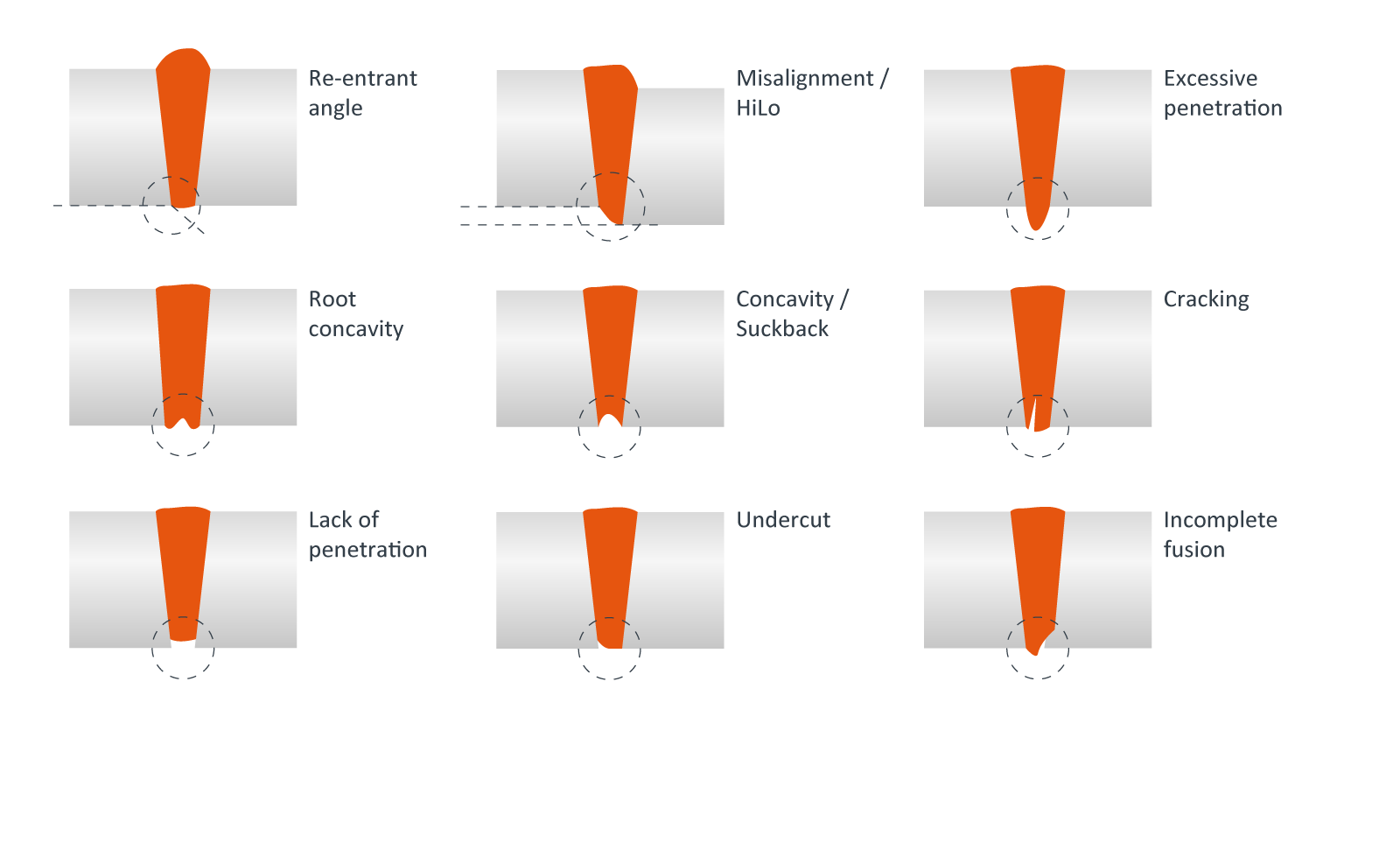

All weld defects have the potential to cause serious problems in tube or pipeline integrity. Defective welds can cause poor fit-up, areas of fatigue, attract corrosion and present a risk of future cut-outs and downtime. Where possible they should be identified and solved before a pipeline goes into operation.

Some of the most common weld defects appear in the graphic below.

Solving defects with grinding

If carried out correctly, post-weld grinding can improve weld strength. Defects such as excess penetration and spatter can be removed and the resulting smooth surfaces provide less opportunity for corrosion to take hold, while allowing smooth progression of cables or pipeline contents. Welds can be shaped to improve their coatability. Grinding welds can ensure they meet design specifications, thus allowing projects to proceed efficiently. Grinding/flushing of the weld is an established method for improving its fatigue performance. This eliminates the stress concentration created by the weld profile and removes the inherent weld toe flaws at which fatigue cracks typically initiate.

Grinding methods

Grinding a weld involves applying abrasive pressure to remove excess material. Methods include angle grinders, wire wheels, coated abrasive belts and bonded depressed centre wheels among others. For internal welds within tubes or pipelines, where welds can be complex and varied, a flap disc is the most effective method. These consist of densely layered abrasive cloth ‘flaps’ glued radially to a backing plate. Flap discs are ideal for internal pipeline welds as they are capable of grinding both simple butt welds and flexible enough to grind more complex welds such as t-joints. Operators can vary the pressure as required, making it easier to achieve contours in the metal and ensuring a high quality surface finish. Flap discs have a long product life and cooler operation than other methods, safer in the potentially dangerous environments of energy production.

Accessing internal welds with OMS robotic grinding system

Reaching welds inside pipelines has traditionally been challenging. The new OMS robotic grinding system (SmartGrind) uses our state-of-the-art Agility crawlers and award-winning weld inspection system to access internal welds, identify defects, resolve defects with grinding before inspecting again to confirm weld compliance. Our crawlers are capable of accessing welds as far as 1km from point of entry, navigating complex sections such as spool pieces and travelling through pipelines from 100mm to 1000mm+. We can reach those welds previously though of as unreachable – and remedy any defects if found. Our modular grinding system uses a mounted flap disc to remove any spatter and excess penetration, grinding the weld to achieve a smooth finish and stronger surface.

OMS SmartGrind

Early intervention prevents later problems

Our weld inspection and grinding system is ideal for use during the pipeline fabrication stage, where any weld issues can be identified and remediated before the expensive installation stage.

System demonstration

OMS now operates a full demonstration rig at our premises in Stansted, Essex. If you are interested in our weld inspection and grinding system or have a project you think we could help with you are welcome to visit us for a demonstration. Please contact our team for help.

Find this article useful? Sign up for more here!

Published: 29.03.2023

[5 minute read]

By Marcus Smiles, Global Manager