The importance of bevelling in pipe welding

Bevelling is a process in which the shape of two pieces of metal is altered, usually by removing the edges, before welding takes place. It is a vital stage in the manufacture of pipes and construction of pipelines because it creates stronger welds that last longer, can support more weight and are capable of withstanding higher levels of fatigue. Bevelling produces an angled surface at the end of a pipe by removing metal through machining, cutting with water jet or flame, or grinding.

Stronger, more robust welds

In pipeline construction every weld is a critical piece on which the integrity of the entire structure depends. Operators are hugely invested in ensuring welds are strong, robust and meet stringent project specifications, particularly in complex sections such as spool pieces and risers. Bevelling pipe ends helps to ensure that these welds are as strong as possible but it can be slow and hold up production when time is critical. Both speed and quality are important – bevelling must take place rapidly so that bottlenecks do not occur, yet it must meet high specifications to ensure welds are strong.

Understanding pipeline geometry

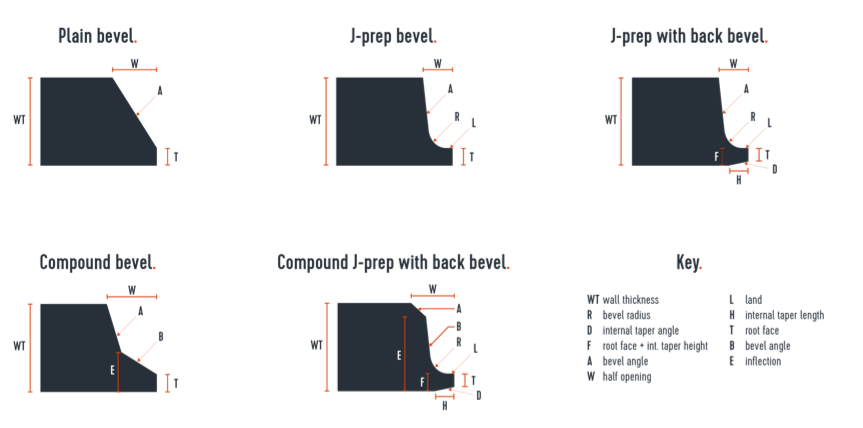

Most industrial bevelling processes leave the metal with one of the shapes below, which have varying levels of complexity. To make sure bevelling is effective, operators must have a thorough understanding of pipe bevel geometry so that the best possible fit-up can be achieved before welding. We wrote about the importance of understanding pipe bevel geometry.

Bevel360 – eliminating doubt about bevel compliance

The OMS Bevel360 scans pipe ends in seconds, producing a 360° laser profile that provides operators with unrivalled insight into pipe bevel geometry and eliminating doubt about bevel compliance. It measures most common bevel types and pipe sizes between 6” and 32” and wall thicknesses up to 45mm. Data is sent to the cloud where it is stored and can be accessed easily by authorised staff, from anywhere in the world.

Rapid go/no go indicator

Our BevelPro software, developed in-house by our skilled software team, analyses the data and gives an easy-to-understand red and green go/no go indicator. An amber indicator gives the operator a warning that tolerances are being approached and an option to investigate further. Rapid results mean that production can continue seamlessly while any potential issues are identified quickly before they can cause stoppages.

New and improved – the Bevel360 Mk II

Since OMS launched the Bevel360 in it has been used successfully on many major oil and gas projects throughout the world. Most recently, OMS worked on the Ichthys II onshore project at McDermott’s facility in Batam, Indonesia, measuring more than 2,000 joints and helping maintain unprecedented rates of production.

Several years of successful operation have provided our R&D team with vital information that has allowed us to make significant improvements to the Bevel360. OMS has recently launched the Bevel360 MK2, which has been developed using our own experiences in the field and suggestions from our clients. It includes:

Wireless battery driven power to increase robustness and avoid cable issues

A new laser acquisition head equipped with the latest generation lasers, which are less prone to spurious readings related to reflective surfaces

Revised data post-processing algorithms based on lessons learnt from MK1 system

A redesigned laser head to reduce laser misalignment issues on site

Simplified rotational drive and more robust encoder

Faster cycle times for productivity

Speeding up production while increasing weld quality

The Bevel360 MK2 is an even more robust tool, providing the most comprehensive bevel information on the market and allowing clients to speed up production while increasing the quality of their welds, and therefore the integrity of their pipelines. If you are interested in the Bevel360 or have any bevelling challenges our team is always on hand to answer any queries. Contact them

Find this article useful? Sign up for more here!

Posted 08.02.2023

(3 minute read)

By Paul Eagle, Sales Director