Laser bevel measurement

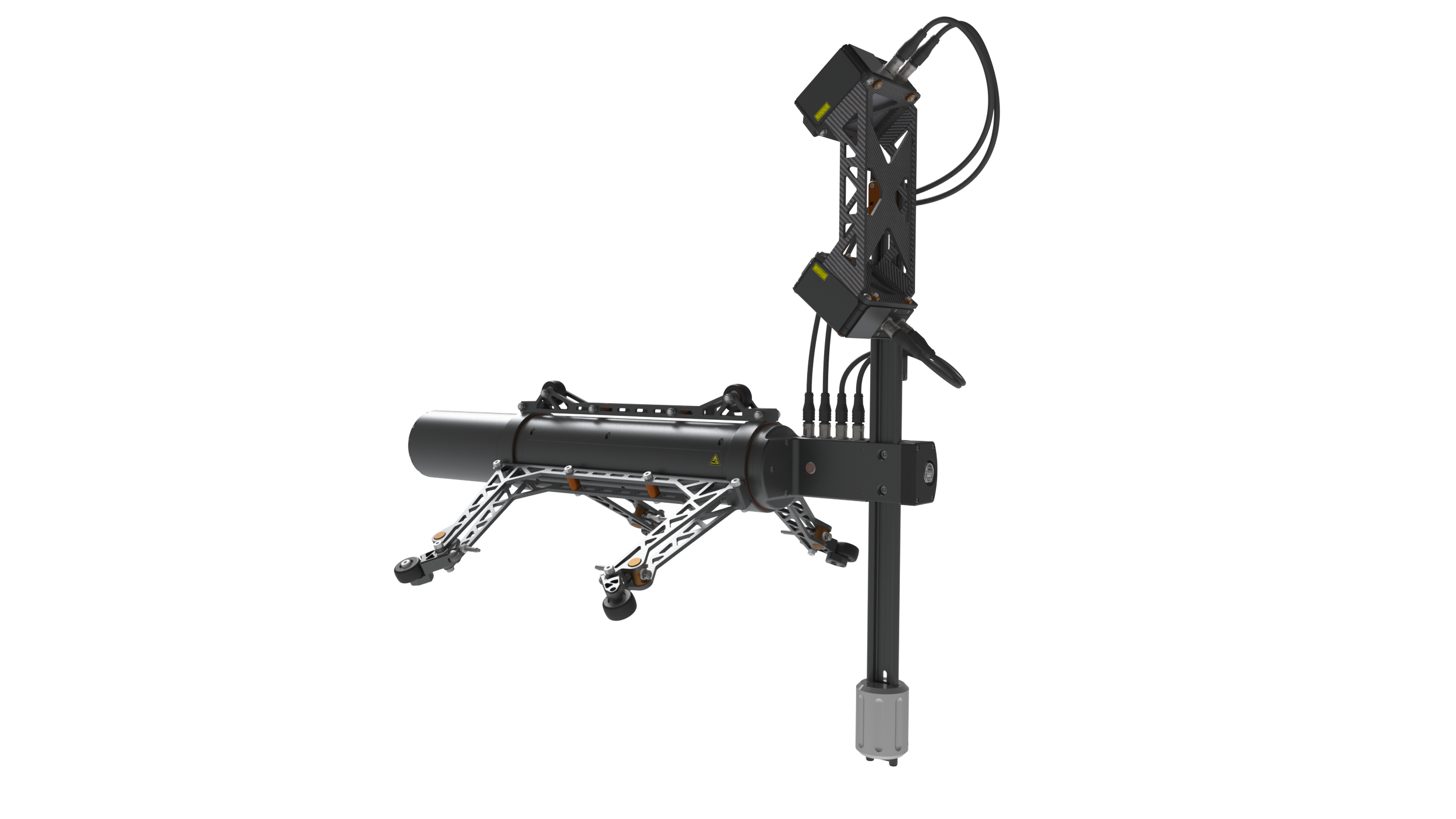

Achieve better pipe fit-up, higher quality welds and improved pipeline integrity. The Bevel360 provides comprehensive information on pipe bevel geometry, helping welding proceed efficiently. In 2022 we released the Bevel360 Mk 2, a new and improved version of the tool.

Latest improvements

Wireless battery driven power

New laser acquisition head for improved readings on reflective surfaces

Revised data post-processing algorithms

Redesigned laser head reduces misalignment issues

Simplified rotational drive and more robust encoder

Faster cycle times for productivity

Key features

Total 360 degree coverage of the bevel

Go/ no-go in 25 seconds

Allows production control of bevel quality

Pipe sizes from 6” to 32”

Wall thickness up to 45 mm

Measures most common bevel types

Bevel measurement system

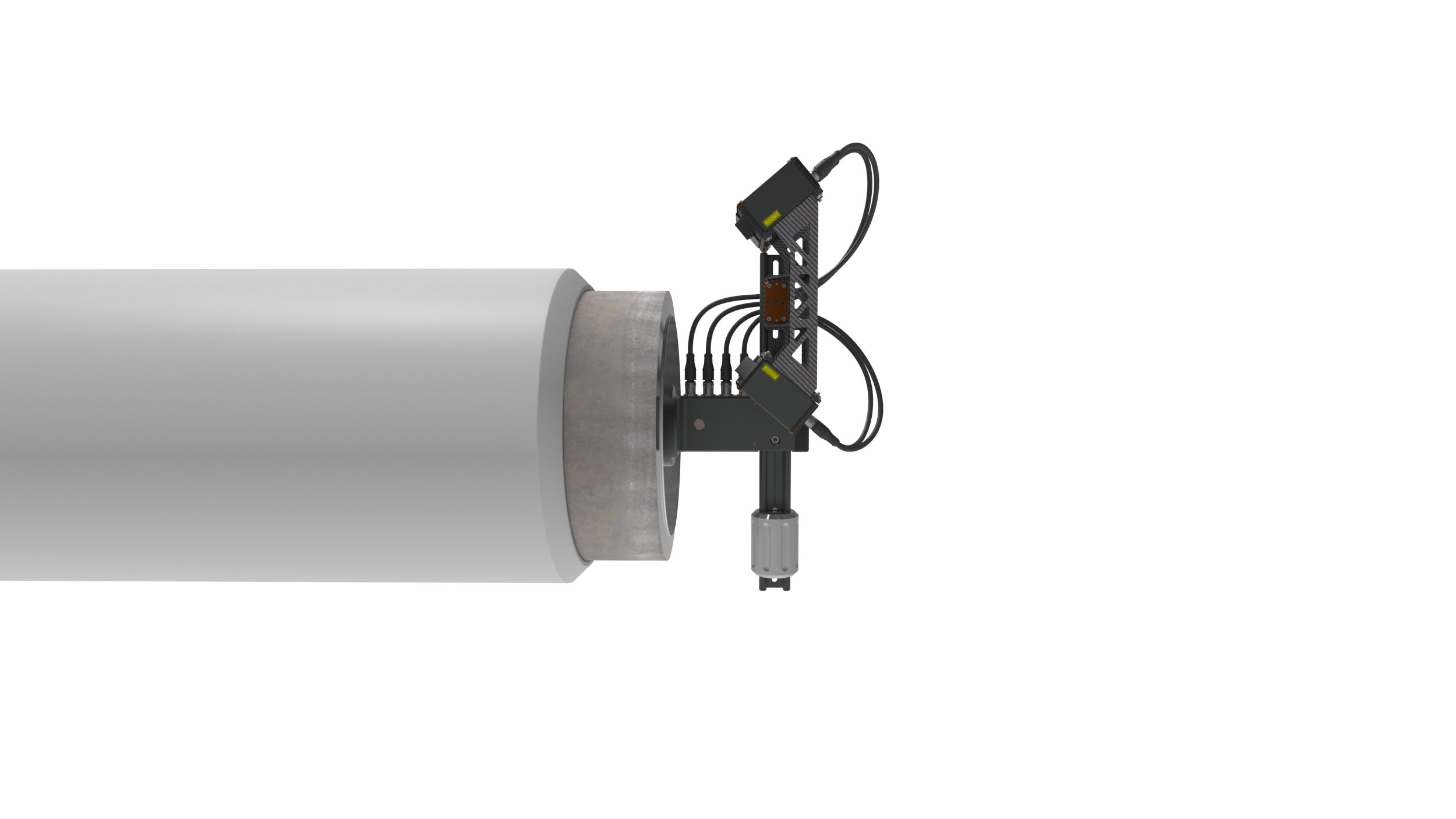

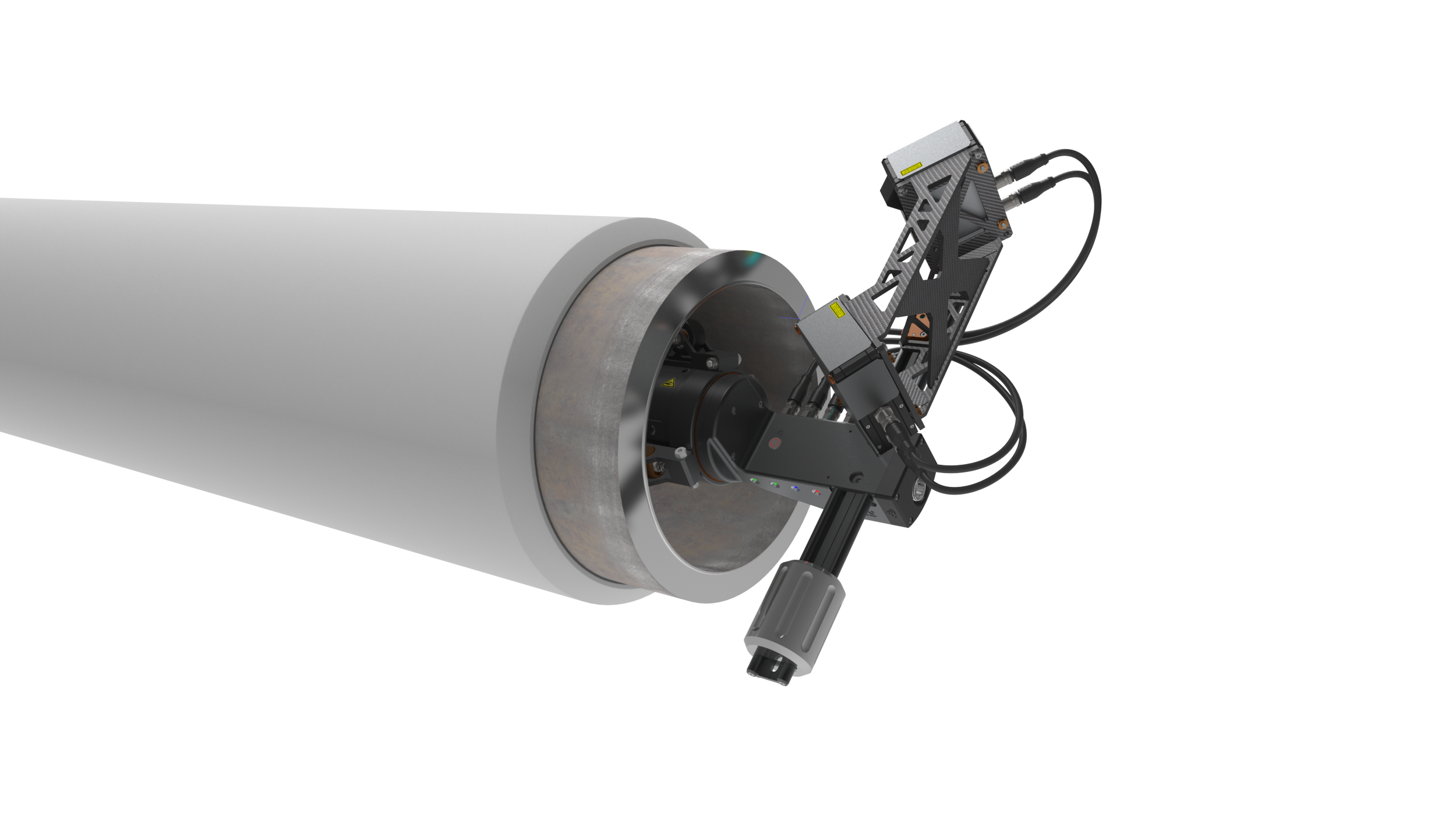

The Bevel 360 laser bevel measurement tool eliminates doubt about bevel compliance, providing the user with an unrivalled insight into critical pipe bevel geometry. Improved understanding of the pipe bevel shape means welding can be a more efficient, streamlined process. The system can be integrated in-line with your facility, allowing for uninterrupted production and further improving efficiency. It can be deployed immediately after bevelling, prior to pipes being moved into production and can perform a complete scan of a pipe end in as little as 25 seconds. This produces a 360 degree measurement profile of the bevel.

Bevel 360 software - go/no go indicator

Once the bevel has been measured, the user receives a simple green or red go/no-go indication via Bevel 360 software, with the option to investigate bevel parameters in greater detail. The amber indication is an early warning that bevel tolerances are being approached.

Pipe bevel geometry

Pipe bevel geometry information is vital for pipeline engineers, welders and quality control inspectors. Accurate bevel geometry leads to more efficient pipe fit-up, improved welding and superior pipeline integrity. Prior to welding, verifying the shape of a bevel is a crucial consideration for pipeline construction.

Plain bevel

J-prep bevel

J-prep with back bevel

Compound bevel

Compound J-prep with back bevel