World-leading inspection and remediation partners.

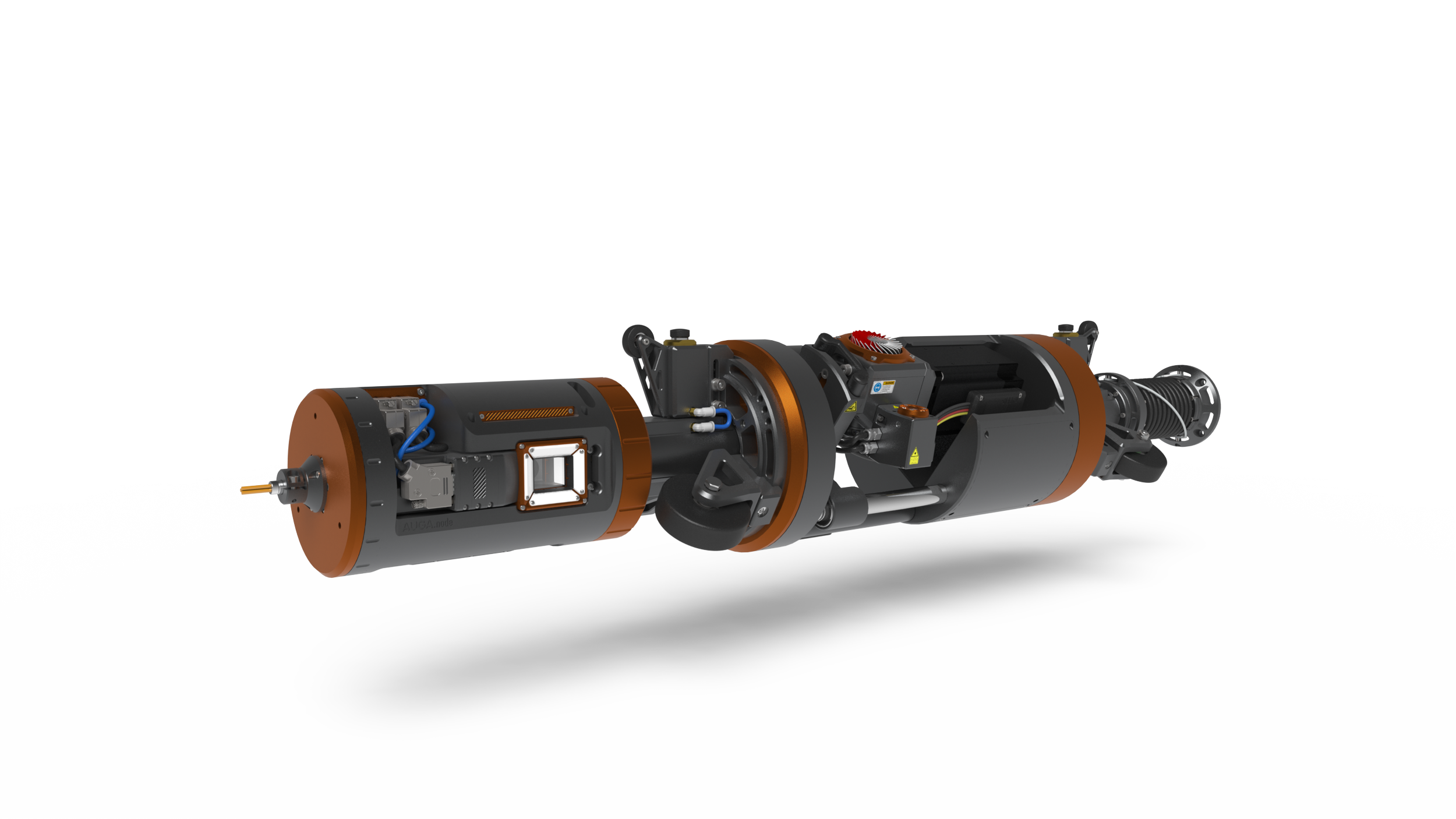

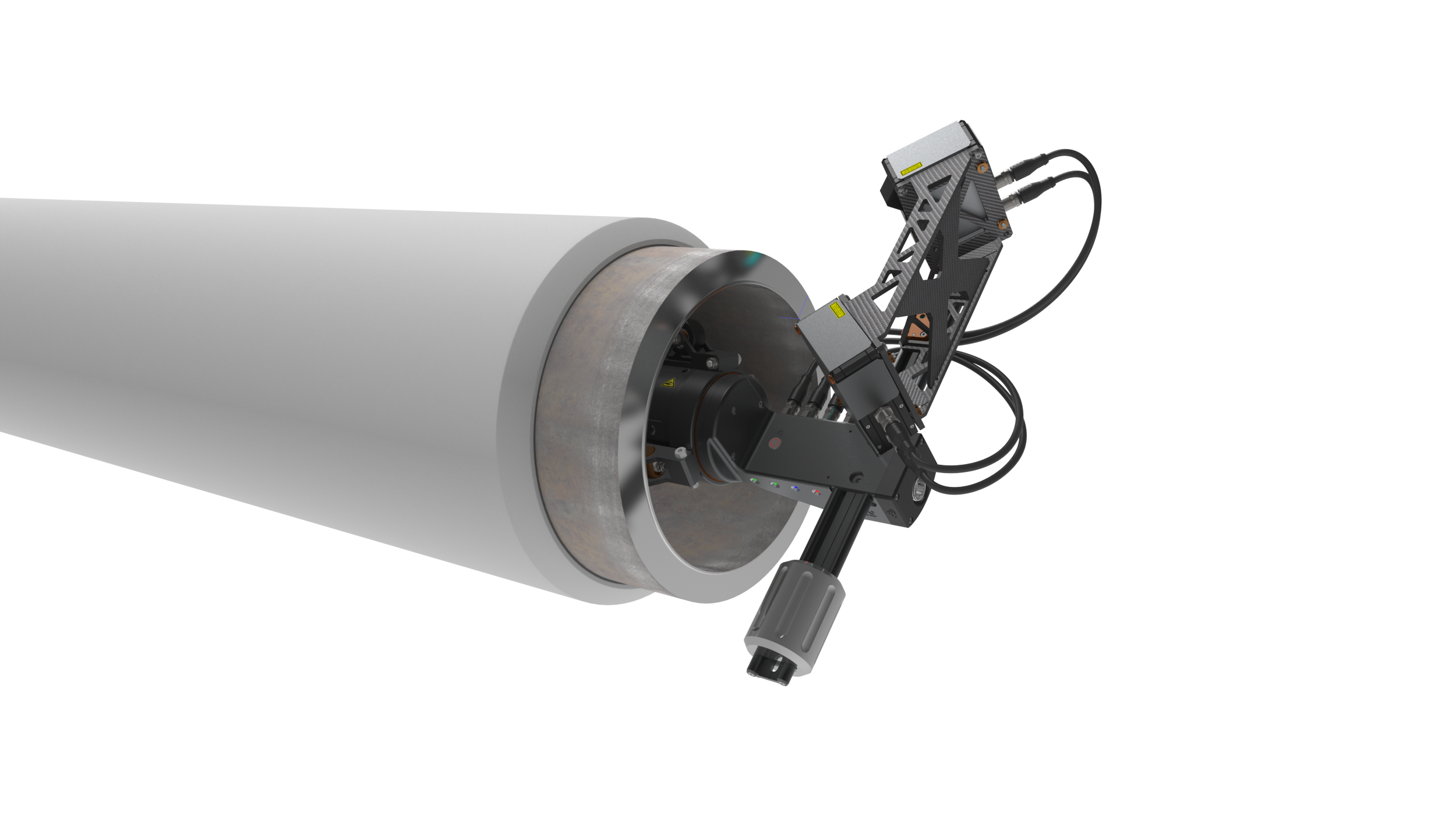

We are a leading measurement, inspection and remediation company working within the energy sector with over 20 years' experience developing innovative solutions for the energy sector. OMS crawlers, tools and services deploy on major global energy projects, to support and deliver critical requirements.

Pipe-end Measurement

Weld Inspection

Remediation

Services

Industry sectors

Independent verification and expert advice

-

Guide to weld inspection

Every stage in energy production depends on good quality welds. Each weld is a critical link on which the integrity of an entire system rests. Weld inspection plays a vital role in ensuring pipelines are strong, safe and long-lasting.

-

Guide to pipe measurement

Pipeline integrity is an aspect that underpins every pipeline in existence and is a critical consideration for all operators regardless of the company size, location or length of the pipelines they control.

-

Guide to robotics in oil and gas

Robots have been in use in oil and gas production since the 1950s and are now deployed across every area of the industry. Increased numbers of robots has enhanced operations, reduced costs, improved safety and increased asset performance.

-

Independent verification

OMS provides impartial, factual and objective advice that helps companies maintain and protect their assets more effectively, reducing safety risks and maintenance costs.

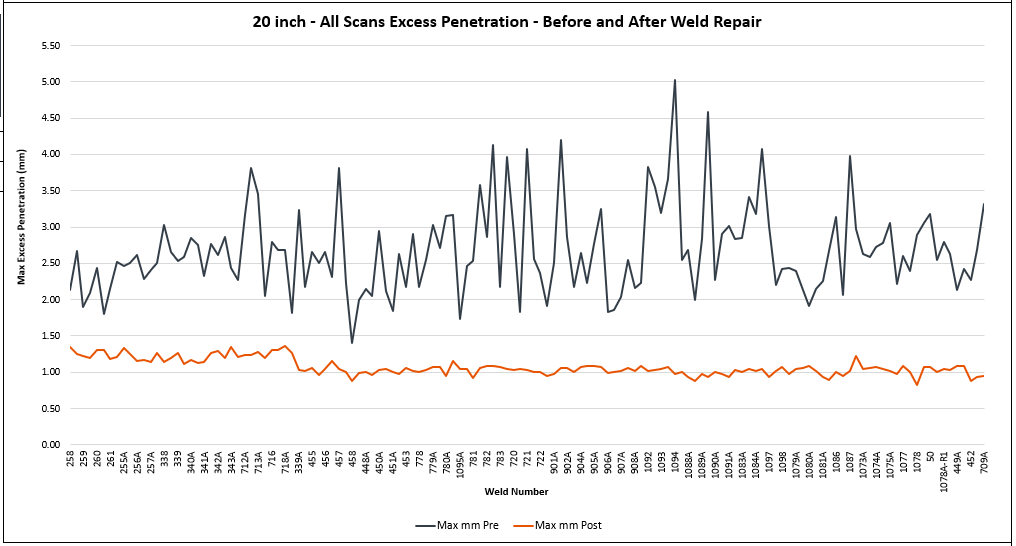

Our projects

“Congratulations to the McDermott, Butting, OMS, PIH, Remacut, WASCO, and ShawCor teams on completing safely the INPEX Phase 2a double jointing scope in PTMI Batam, Indonesia. More than 2000 joints welded, inspected and coated with exceptional quality and unprecedented production rates for CRA pipelines. Tremendous teamwork and performance under challenging pandemic circumstances, looking forward to a successful offshore campaign later this year!”

OMS and the energy transition

“Technological advances made by innovators in the energy sector will speed up the world’s transition to sustainable power. Companies like OMS, with expertise in finding effective solutions to challenging situations, are ideally placed to support clients in a sustainable future.”

Clean energy is an exciting developing market for OMS. We offer a range of solutions to help clients in offshore wind and nuclear energy overcome various challenges. We hold several patents in the clean energy field and our in-house R&D and engineering teams are continually evolving our capabilities in line with the challenges our customers are facing.

Offshore wind

Nuclear power

Project requirements form

Fill in the form below to let us know how we can help you.