Long range inspection of critical welds

Inspecting welds at a long distance is an important challenge for the oil and gas industry. Inspection, particularly of welds in critical sections such as spool pieces and stalk tie-ins, is vital for successful pipeline installation and effective asset maintenance but getting the technology to the desired location can be very difficult. Test sites can be a considerable distance away from the point of welding and many are located around a complex system of bends.

OMS long-range inspection technology demo

Innovative solutions for the oil and gas industry

With over 15 years’ experience developing innovative technology for the energy sector, OMS has a dedicated R&D team whose aim is to create systems to solve some of these challenges. We have created a range of robotic crawlers to deploy our award-winning inspection system into some of the most difficult-to-reach locations, pushing the range of what is possible.

Self-driving to 1km

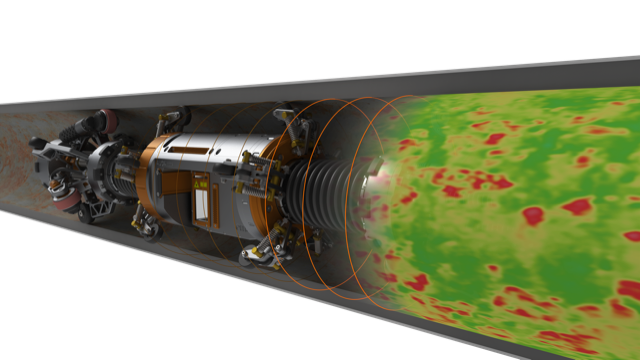

The AUGA.node, our latest device, is self-driving, moving itself into location using powered wheels which adapt to variations in pipe size and shape. Capable of travelling to inspection sites as much as 1 kilometre away without the need for push rods or other methods of transport, the AUGA.node moves easily around complicated pipeline systems involving multiple bends and elbows.

Successful inspection of critical welds

OMS crawlers can reach some of the trickiest locations, allowing pipeline installation contractors to carry out inspection of critical welds such as those found in spool piece, steel catenary risers and stalk tie-ins.

Once in position our inspection system uses its ultra HD cameras and state-of-the-art lasers to capture data that allows our software to provide pipeline operators with a comprehensive picture of a weld or pipeline interior. This technology helps engineers make rapid, accurate decisions in the field and increases the likelihood that project deadlines will be met.

Project experience – large project in the Middle East

OMS was hired by a major EPC contractor to inspect topside and riser welds for a large replacement project in the Middle East. Our AUGA.node weld inspection system was deployed successfully via long-range fibre optic cable in 10”, 24” and 31” pipes in riser, reducer and topside sections, navigating through 5D bends and 1.5D elbows and providing extensive data to aid the installation process.

Robust operation in harsh environments

OMS robotic crawlers are robust, capable of operating successfully in the harsh environments and extreme temperatures of the energy industry. Tough enough to handle 24-hour production cycles offshore for long periods of time our crawlers can reach some of the hardest locations in oil and gas pipes, helping operators inspect and maintain their equipment effectively and reducing the chance of downtime, cut-outs or pipeline failure.

Modular design with repair capabilities

The AUGA.node is a modular system which can be equipped with whichever tools the job requires. We offer ultra HD cameras, state-of-the-art lasers, powerful LED lighting and our new SmartGrind™ system to allow simultaneous inspection and repair of out-of-specification welds. For more information on our long-range inspection capabilities please contact us here.

Find this article useful? Sign up for more here!

Posted 16.02.2021

[5 minute read]

By Paul Eagle, Sales Director