OMS robotic weld remediation service helps client achieve stringent project specifications

SmartGrind weld remediation system

OMS has recently completed an extensive weld remediation project at a major oil installation in Saudi Arabia. Our team attended the site where they deployed our remote inspection and remediation technology to assess welds throughout many kilometres of newly fabricated pipeline and remediate areas of high excess penetration or sharp edges. Following remediation, the welds were reassessed using 3D laser profiling to confirm project specifications were met, allowing coating to proceed efficiently, and avoiding expensive cut-outs and re-welding of the joints.

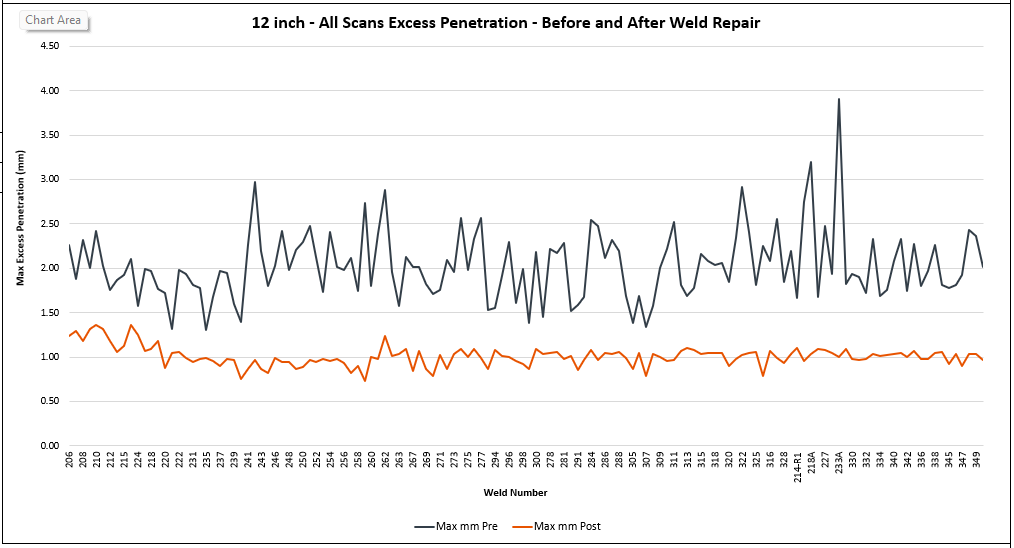

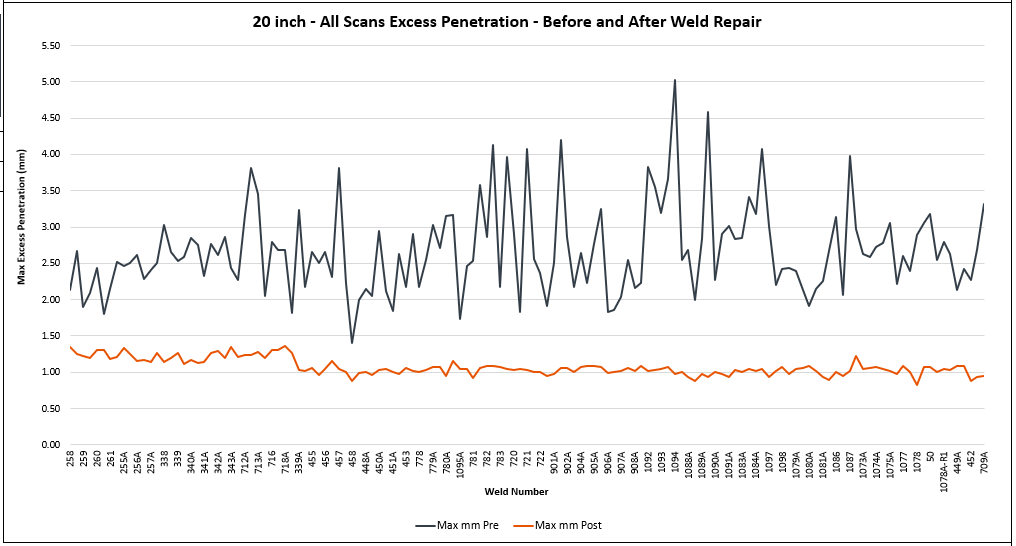

Less than 1.5mm tolerance achieved throughout

The site owner/operator had specified stringent excess weld penetration tolerance of >1.5mm. In the graphs below, the grey line indicates the level of excess weld penetration before SmartGrind remediation, and the orange line indicates the level post-remediation. These clearly demonstrate that excess penetration has been reduced to a level well below the project tolerances specified by the owner/operator.

12 inch pipe remediation results

20 inch pipe remediation results

Following remediation, the pipeline proceeded to the coating stage, with work carried out by our valued partners at CRTS Global. The project owner and operator could be reassured that their pipeline was installed with the highest possible weld standards.

‘Reducing excess penetration and removing sharp edges improves weld quality’

Alex Felce, OMS CEO, said, ‘Reducing excess penetration and removing sharp edges through internal remediation improves weld quality and means that the coating application will be more effective and pipeline integrity increased. In recent years we have seen that installation owners are strengthening commitment to pipeline safety by increasing standards throughout the industry. What would previously have been highly stringent tolerances are now standard practice, which is good news for asset integrity. Our team were extremely pleased with this project, which demonstrates how successful SmartGrind inspection and remediation technology is at repairing welds that do not meet specification or will cause issues for internal coating.’

Technical details

Our site team used OMS SmartGrind remote inspection and remediation system, which has been verified by Saudi Aramco. This technology is a modular addition to our award-winning AUGA.node inspection system, which uses a mounted flap disc to shape welds, improving coatability and the quality of the pipeline. In this particular project, the system was deployed onto pre-fabricated 500m sections of pipeline via state-of-the-art AGILITY range robotic crawlers, which are capable of navigating complex pipelines with multiple elbows, bends and vertical sections. It can also be attached to the ILUC or deployed via push-rods.

Challenging inspection and remediation project?

Our highly skilled team has significant experience solving challenging weld inspection and remediation issues. If you have an upcoming project we may be able to help. Contact our team for assistance.