SmartGrind datasheet

Modular attachment to the award-winning AUGA.node weld inspection system. Identifies and solves a wide range of weld defects. Equipped with HD cameras and state-of-the-art laser sensors which collect data that allows targeted, localised repair or full flush of the LSW. Driven by an automated software algorithm, the grinding head avoids the possibility of subjective human error. Rapid defect remediation allows production to proceed with maximum efficiency. Following repair, welds are rescanned to confirm they have achieved project criteria. Identify and solve excess penetration, spatter, sharp edges, flush, scale residue and crystallisation.

Benefits

Localised grinding

Eradicate human error

Reduce risk of parent material loss

Smooth, efficient installation

Reduce need for repairs

Improved weld surfaces

Improved coatability

Features

Integrate with other equipment

Various deployment methods

12” - 60” nominal pipe sizes*

Radial or LSW grinding

Multiple bends

CS or CRA pipe

500m travel

*8” system under development and due mid-2025

ILUC configuration

AGILITY configuration

ILUC configuration

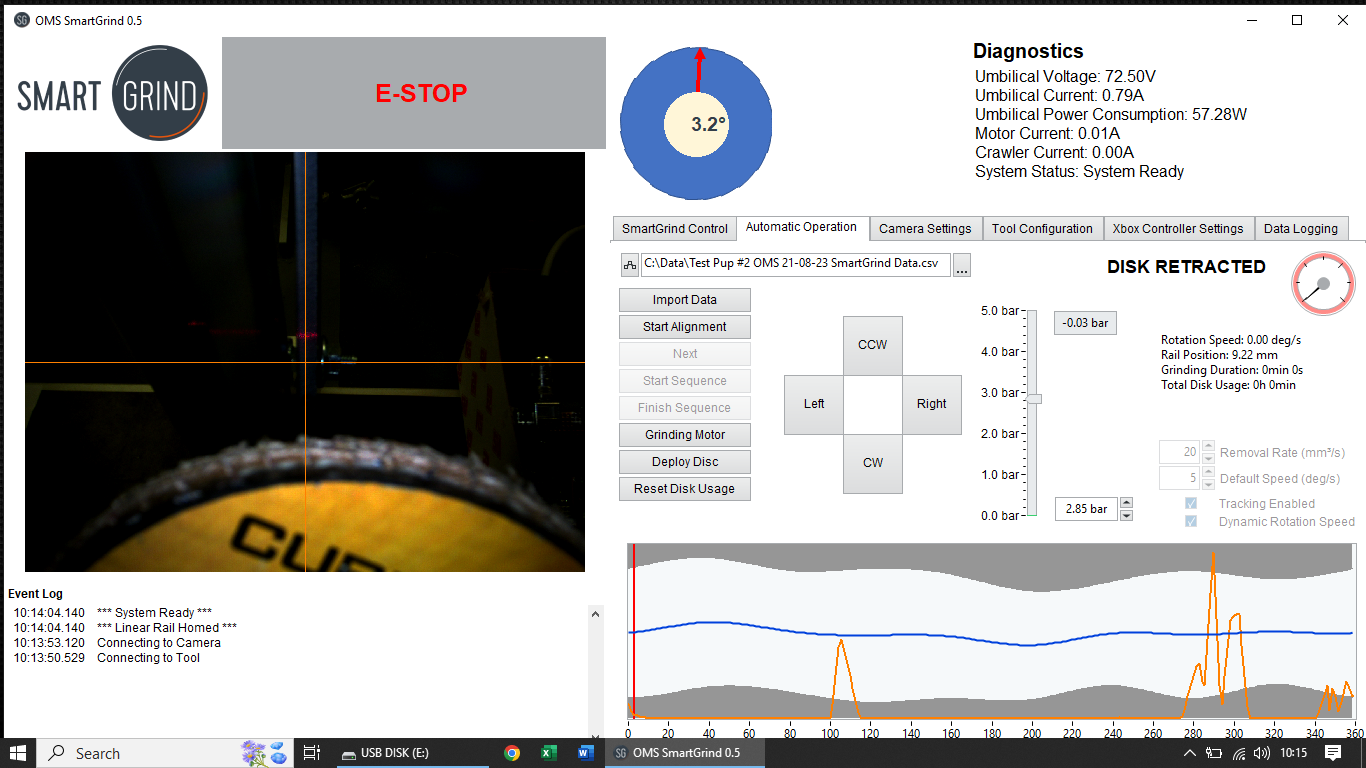

Software and automation

User interface

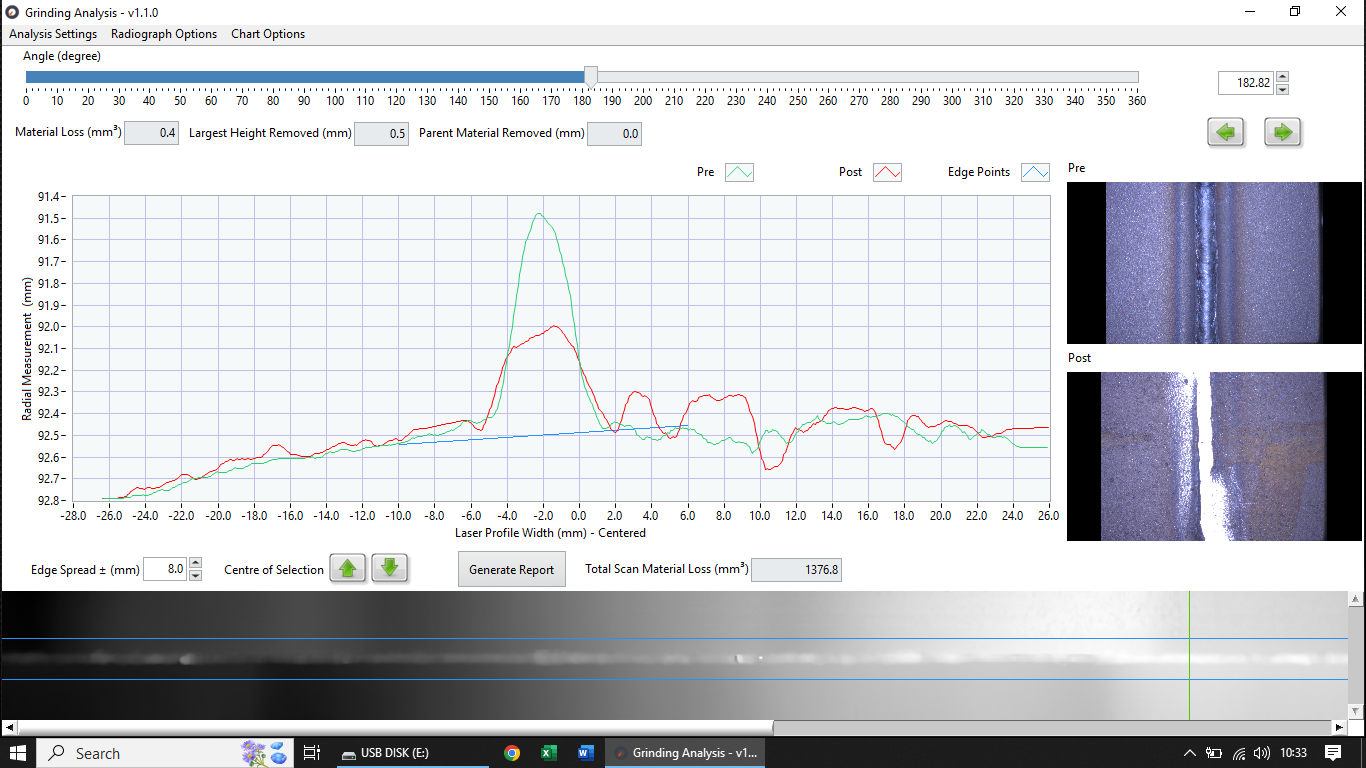

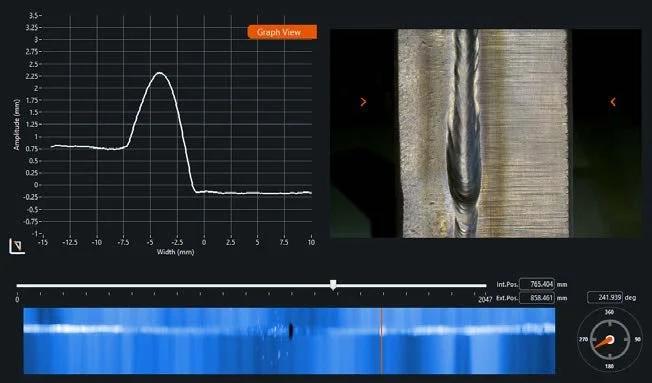

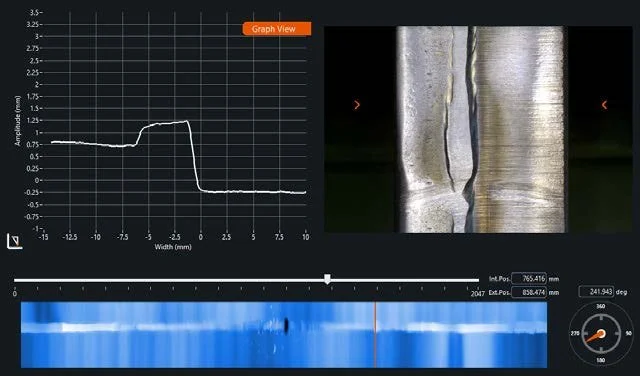

Graph shows material peaks for removal

Flat orange line shows tolerance baseline

Validation of material removal

Shows pre- and post-overlay material