Wingbox Checker

Key features

Survey of the inside of tapering carbon fibre wingbox segments

Rapid dual laser inspection using a crawler

One-off special design to measure critical stress concentration points

Accurate and repeatable measurements for world’s largest and most advanced plane

Full data management and CAD model

Accurately measure internal wingbox dimensions

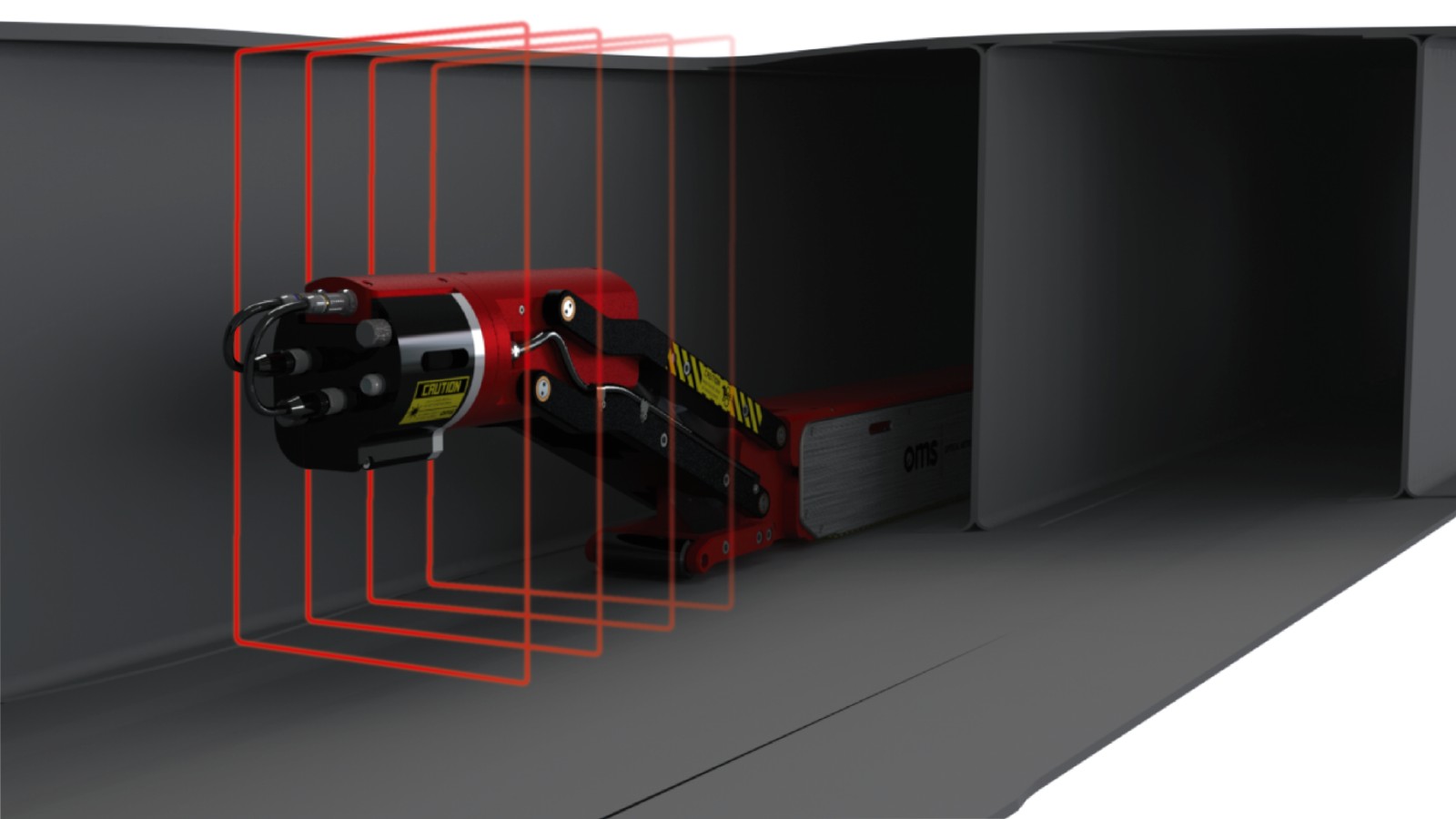

OMS was approached by an aerospace organisation when they needed to survey the inside of various tapering carbon fibre wingbox segments, ranging from 100 mm square to 700 x 500 mm, over a distance of twelve metres and accurate to within 0.25 mm. Our solution had to measure cross-sections of the inside spaces at regular intervals and then stitch the measurements together to provide a CAD model of the entire Boeing Dreamliner tail plane interior. The survey had to take less than an hour per section and measure the corner radii of the box wing sections, critical stress concentration points, accurately.

Solution for the most advanced aircraft

OMS created a professional solution that would work for the world’s largest plane manufacturer on their most advanced aircraft. Our system used laser triangulation devices to co-ordinate each measurement into a laser tracker, maintaining itself centrally in the structure.

Wingbox inspection process

Steer the inspection unit using crawler tracks. The device ‘drives’ along a flat carbon fibre composite structure, while being steered to keep it central within the structure

Maintain the tool in the centre. Using laser ranging sensors on either side we kept the device in the correct position over a twelve metre range.

Keep the laser head centralised. Our parallel motion system allowed the measurement head to be raised and lowered.

Measure a rectangular structure of varying size. We used three different heads to address the required ranges, one of which required two laser sensors to obtain the necessary accuracy and range.

Determine the spatial position of each measured cross-section. Using a laser tracker we measured the tooling ball location as it travels through a circle in space, ensuring further accuracy. Resulting information was fed into a software package which collected all measurement data for storage and analysis