J-tube inspection

Latest news: OMS successfully completes renewable energy project to inspect internal J-tube welds on time and within budget - August 2022. Read full story.

J-tubes guide export power cables from wind turbines to the seabed. An essential part of the wind turbine foundation structure, cables can be impeded, damaged and even blocked by excess weld penetration and internal pipe ovality. As energy regulators turn their attention towards renewable sources, more and more stringent standards are being applied with a particular focus on pipe shape and weld quality. OMS has developed a solution specifically aimed at solving these challenges in the wind energy industry.

Our award-wining weld inspection service collects real-time visual and laser data on the internal condition of your J-tubes, allowing you to:

Achieve project specifications

Improve asset lifetime

Make better quality decisions

Mitigate project risks

Reduce costs

Grinding module

Inspect, repair, inspect again

OMS AGILITY robotic crawlers can access welds throughout J-tubes, including in the most difficult to reach areas, using the latest in camera and laser technology to capture comprehensive data on internal pipe condition. The inspection system assesses pipe ovality, HiLo misalignment and weld root penetration, identifying defects, areas of corrosion and obstructions. A state-of-the-art grinding system is deployed to carry out any necessary remedial work before the J-tube is inspected again and weld quality confirmed.

100mm - 800+mm pipe diameter

Robust, reliable, easy to use and portable technology

Proven system used successfully in multiple major energy projects worldwide

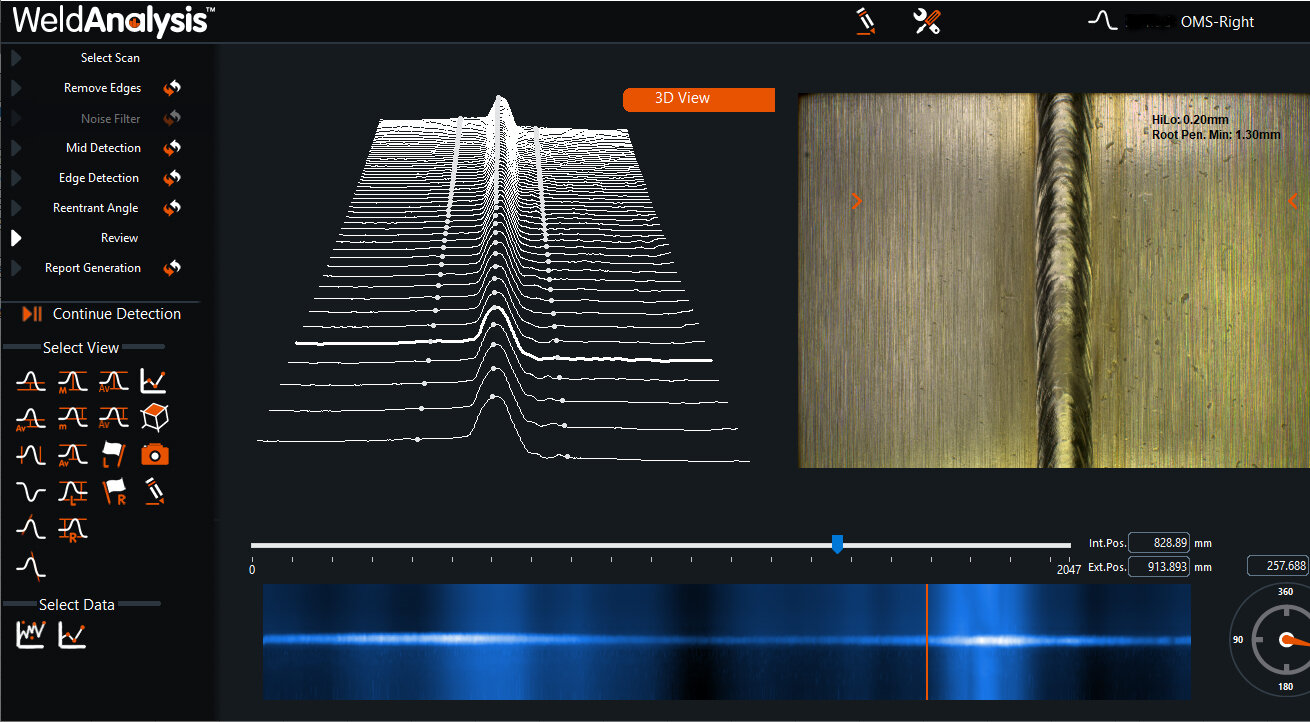

WeldAnalysis software

Processes data from weld inspection tools

Allows quick analysis of the weld

Weld: pre-grinding

Weld: post-grinding

AGILITY.micro

AGILITY.mini

AGILITY.max