Unrivalled laser pipe-end measurement and fit-up

OMS has been providing ground-breaking laser end measurement and fit-up services to the energy industry for more than 20 years. As the market becomes more and more buoyant our services are currently more popular than ever, because we help our clients reduce their project costs, mitigate risks, increase efficiency and install higher quality assets. Contact us to learn how we could help your project.

Measure

Comprehensive laser pipe-end dimension information with the OMS AutoTool.

Fit-up

Achieve optimum fit-up with OMS SmartFit, and build higher quality assets.

Succeed

Achieve project specs, reduce costs and risks with OMS technology and services.

Projects

Our team was recently asked to attend a project where our client had encountered significant problems. Issues discovered while on the pipe-lay vessel caused problems which meant our client lost ten days of expensive vessel time. Our operators and technology were deployed and were not only able to remedy the issues, but managed to bring the project back to schedule, saving our client valuable time and enabling the installation process to progress smoothly.

OMS offers agile solutions to client problems. Our portable technology and experienced operators mean we deploy rapidly and arrive on-site to solve problems as soon as possible. Contact us to find out how we can help.

Pipe measurement services

We have been measuring pipe ends for more than 20 years and in all that time, have never found one that is completely round. Measuring pipe ends with the OMS AutoTool provides data which can be used to sort, group, sequence and rotate pipes so that they fit together in the optimum way. This is a cost-effective, tried and tested service that leads to better fit-up, stronger welds and longer lasting pipeline, while also improving efficiency and facilitating smooth installation.

Autotool

Industry-leading tool

Best information on the market

Traceable data

PipeCHECKER software

Combines with SmartFit

Tried and tested

Accurate to 0.05mm

Reliable and robust and easily transportable

ID, OD, WT and OoR measurements

2,048 measurements

Pipe fit-up: SmartFit

OMS SmartFit™ technology provides the most comprehensive fit-up information on the market. Working in harmony with our measurement tools, SmartFit™ helps clients achieve the best possible fit-up, even in complex critical pipeline sections such as spool pieces, risers and stalk tie-ins. We have recently improved this powerful analysis software, which helps operators to meet project specifications, bring projects in on time and within budget, build the strongest possible pipelines and extend asset lifetime.

Revolutionising pipe fit-up in oil and gas - read our latest blog.

Features:

Achieve optimum fit-up, particularly in critical pipeline sections

Fit-up all pipe, including those that are out-of-specification

Group, sort and sequence pipes

Select ‘golden pipe’ for critical sections

Minimise rejected pipe

Sophisticate ovality analysis and optimal material nesting

Optional global software support

Benefits:

Build stronger, longer lasting pipelines

Reduce weld cut-outs and fit-up time

Improve weld quality and avoid problems offshore

Improve safety

Mitigate project risks

Achieve project standards

Bring projects in on budget

Bevel360: Laser bevel measurement

Improve weld quality, increase welding process efficiency and build stronger pipelines with the Bevel360, which uses state-of-the-art lasers to provide comprehensive information about a pipe bevel, eliminating doubt about bevel compliance.

Total 360 degree coverage of the bevel

Go / no-go in 25 seconds

Allows production control of bevel quality

Pipe sizes from 6” to 32”

Wall thickness up to 45 mm

Measures most common bevel types

HiLo measurement

The Open Gap and Closed Gap HiLo Tools measure the HiLo geometry of pipes aligned for welding. Reducing HiLo means stronger welds - leading to higher quality, longer lasting assets. OMS HiLo tools are ideal for critical pipeline sections such as stalk tie-ins and steel catenary risers. They have been used successfully around the world by all major pipe-lay companies and welders.

Features:

Reduce HiLo

Improve weld quality

Install stronger assets

Ensure design specifications are met

Benefits:

Easy to use with magnetic base and calibration/verification stand

Highly accurate + traceable

Industry standard tool

Range of blades available to suit requirement

“Measuring HiLo just before welding confirms the best fit-up selections for critical fatigue-sensitive pipes and reduces the chance of expensive weld-related cut outs.”

Optimal material nesting

Detailed measurement information for complex pipeline sections

Our optimal material nesting service helps clients ensure compliance with complicated and stringent project HiLo specifications. Combining laser measurement with the Autotool and SmartFit analysis, comprehensive information is provided which means installation can proceed efficiently and clients can avoid the use of pup pieces during the time-critical post-metrology stage.

Pipe marking and data

OMS offers a robust and reliable handheld pipe marking system that applies durable 2D data matrix marks with a weather and corrosion-resistant finish. Carried out simultaneously with pipe-end measurement, this is a cost-effective solution that amalgamates all pipe data from mill to seabed. Improve your load-out management, increase operational efficiency and expand automation.

Benefits:

Extra QA/QC check before welding

Improve load-out management

Increase operational efficiencies

Trace pipes throughout entire supply chain

Features:

Robust 2D data matrix marks with a weather and corrosion-resistant finish

Mark and identify all pipes

Easy-to-use handheld scanner

Bluetooth wireless connectivity to OMS pipe collection software

Spool and pipe-lay ovality checker

Verify pipe ovality during the reeling process to ensure pipeline integrity and prolong asset lifetime. When pipe is reeled for offshore laying its ovality can increase during the process. The tensioners that reel and unreel the pipe can affect the shape, leading to areas of stress and potential integrity problems in years to come. Developed following a customer request, the OMS ovality checking system uses a removable ring with mounted laser sensors to monitor pipe ovality in real time.

Prevent problems caused by excessive pipe ovality

Monitor critical factors that can shorten asset life expectancy

Verify ovality conforms to design specifications

Dynamic measurement of ovality during offshore pipelay

Real-time simultaneous measurements from multiple lasers

Suitable for multiple types of pipe and cable

Flexible systems can be modified for most deployments

Suitable for integration with existing systems

Accurate and repeatable

Traceable measurements and results

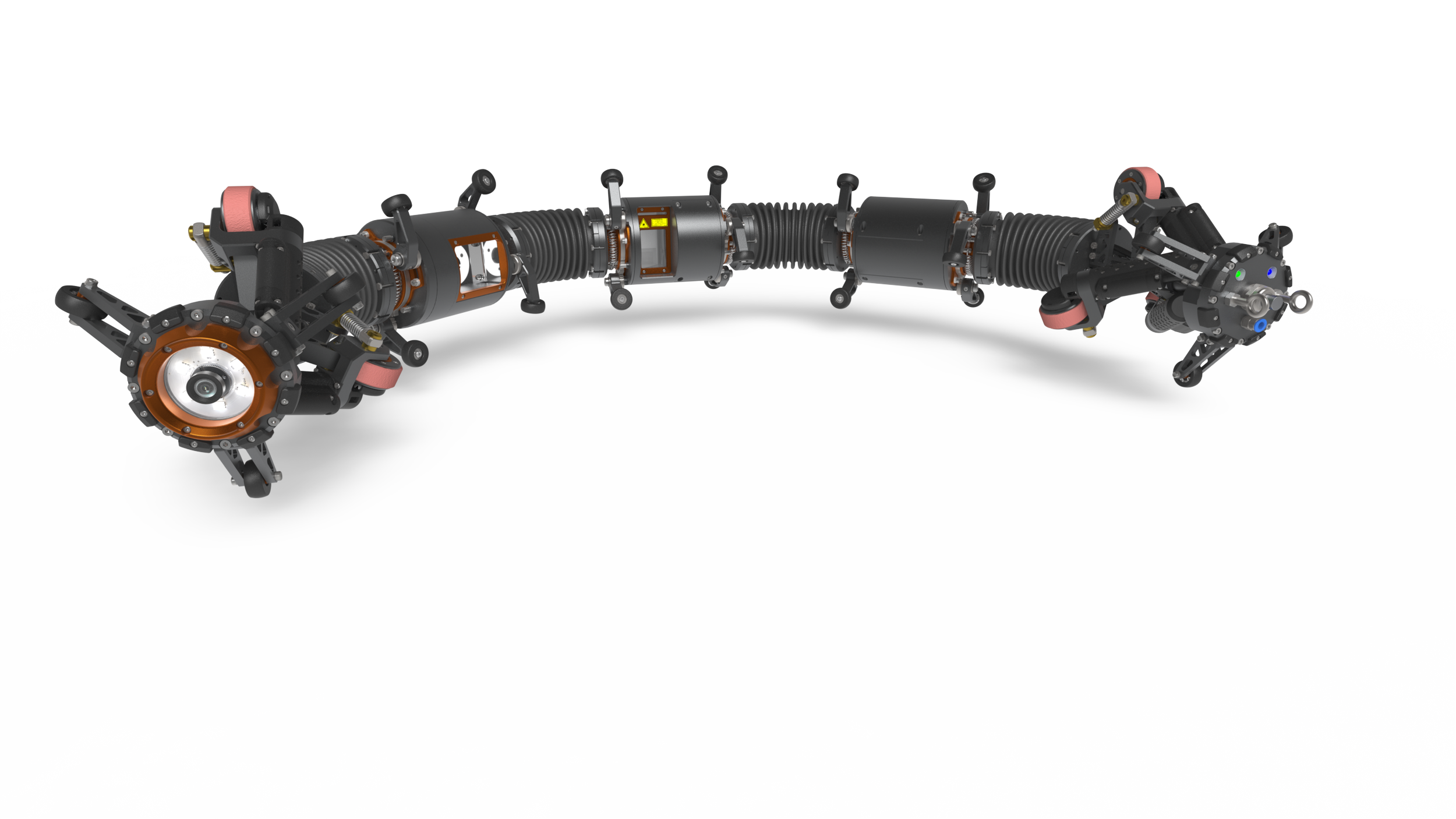

Robotics

Access welds thought to be unreachable with our state-of-the-art robotic crawlers, which deploy award-winning laser and camera inspection equipment. Robust, reliable technology used successfully in major oil, gas and renewable energy projects all over the world. OMS crawlers are portable, easy to operate and capable of travelling 1km+ from point-of-entry. Contact us for more information.

News

Sectors

-

Oil & Gas

OMS pipe measurement technology and services have been used successfully on most major global oil and gas projects.

-

Renewable energy

OMS measures and inspects components in major offshore wind installations.

-

Nuclear energy

OMS works on various projects with major nuclear power operators. Our technology is FAT-tested.